Research and Development

Final Frontier’s Capabilities

Research and Development

Final Frontier’s Capabilities

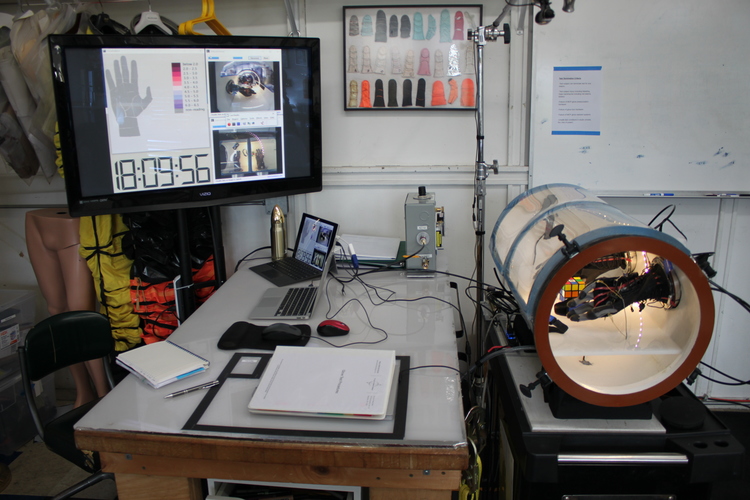

FFD has developed a unique wearable compression measurement system, that allows the wearer to dial in exact compression rates. The system utilizes force sensitive resistors (FSRs) to visualize levels of compression on the legs, abdomen, hands, or elsewhere.

Through years of human testing studies with NASA, FFD has developed a variety of measurement tools to evaluate the range of motion of a person in a garment assembly. This is particularly useful when compared to unrestricted range of motion, for better use-case design solutions.

FFD has invested in a variety of tools to test torque, life cycle, and strength of garment assemblies. This includes how much force it takes to bend a finger or sleeve, how many cycles an elbow can withstand, and how strong a garment assembly is.

FFD's focus on space suit design has a profound overlap with terrestrial safety equipment design. From electrical linesman to firefighters, we are excited to leverage our Personal Protective Equipment concepts for folks on Earth.

FFD's unique skill sets include a deep understanding and experience in inflatables for garments, devices, and structures. We have a variety of fabric welding and sealing techniques available and a variety of problem-solving patterning techniques to make virtually any inflatable concept a reality.

FFD has extensive experience in creating complex assembly models and evaluating them for flow, strength, and function. We use the Solidworks Finite Element Analysis (FEA) suite to analyze pressure drop, deflection, and interference, as well as other critical design factors. Our expertise is in 3D printed, compound surface parts.